In the field of optics, the Abbe value is an important measurement that relates to the dispersion of light in transparent materials.

The Abbe value quantifies how much a material’s refractive index changes with different wavelengths of light, helping to identify its suitability for optical applications. A higher Abbe value indicates less chromatic aberration, meaning light of different colors focuses more accurately, which is essential for quality lens design.

Understanding the Abbe value allows professionals in optics to select the right materials for various uses, from eyeglasses to cameras.

It offers a vital insight into how light behaves when passing through different substances, impacting image clarity and quality. When designing lenses, choosing materials with the appropriate Abbe value ensures that optical devices perform at their best.

As technology advances, the importance of the Abbe value in developing new optical materials continues to grow. By grasping this concept, readers can appreciate the critical role it plays in enhancing visual technologies and understand why it matters in the creation of effective optical systems.

Understanding the Abbe Value

The Abbe value is essential in optics as it relates to how light disperses through different materials.

It helps to understand lens qualities and their impact on visual clarity. This section covers the historical context of Ernst Abbe, the definition of the Abbe number, and its relevance to lens materials.

Historical Context and Ernst Abbe

Ernst Abbe was a German physicist who made significant contributions to optics in the late 19th century. He worked closely with Carl Zeiss and helped improve microscope design.

During his research, Abbe introduced the concept of the Abbe number, which quantifies how different materials disperse light.

Abbe’s work laid the foundation for modern optical science. This was key in developing high-quality lenses for various applications, from microscopes to eyeglasses. His efforts changed how lenses are manufactured and analyzed, leading to better optical performance.

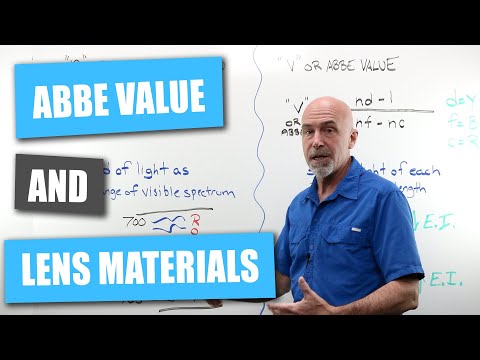

Defining the Abbe Number

The Abbe number, also known as the V-number, measures how much a material disperses light. It is defined as:

[ V = \frac{n_d – 1}{n_F – n_C} ]

- n_d: Refractive index at the d-line (587.6 nm)

- n_F: Refractive index at the F-line (486.1 nm)

- n_C: Refractive index at the C-line (656.3 nm)

A higher Abbe number indicates lower dispersion, meaning less chromatic aberration. Chromatic aberration occurs when different colors of light focus at different points, causing blurry images. Lenses with high Abbe values produce clearer images as they minimize this issue.

Relevance to Lens Materials

Different lens materials have varying Abbe numbers, influencing their optical quality. Common materials include:

- Crown Glass: High Abbe value (around 59), low chromatic aberration.

- High Index Glass: Moderate values (like 42 for index 1.60), more dispersion.

- Plastic CR-39: Abbe value near 58, balancing weight and clarity.

Choosing the right lens material is crucial for vision correction and optical devices.

For example, high Abbe value lenses are preferred in applications where clarity is vital, such as in prescription eyewear and camera lenses. Understanding these values helps professionals make better decisions in optics.

Influence of Abbe Value on Optical Devices

The Abbe value plays a crucial role in determining the performance of various optical devices. It affects the clarity, color accuracy, and overall effectiveness of lenses and prisms. Understanding its influence can help guide choices in eyeglasses, safety eyewear, and specialized optical applications.

Impact on Eyeglasses and Safety Eyewear

Abbe value significantly affects eyeglasses, as it measures how much light disperses when passing through the lens material.

A higher Abbe value means lower chromatic dispersion, resulting in clearer vision for the wearer.

For example, materials like crown glass have a higher Abbe value, leading to less chromatic aberration compared to polycarbonate or flint glass. This difference is crucial for eyeglass wearers who demand high optical performance.

In safety eyewear, the right Abbe value ensures that the lenses provide accurate color perception while protecting the eyes. Being aware of the Abbe value can help manufacturers design better safety glasses that do not compromise optical quality for strength.

Design Considerations for Lenses and Prisms

When designing lenses and prisms, engineers consider the Abbe value to ensure optimal performance.

Lenses with a higher Abbe value are better suited for applications requiring minimal chromatic aberration, such as telescopes and microscopes.

Key considerations include:

- Refractive Index: Balancing Abbe value with the refractive index is essential to maintain focal length and lens thickness.

- Material Selection: Choosing between glass types, such as crown and flint glass, can influence the optical performance of the final product.

Using high Abbe value materials can lead to the development of achromatic lenses, which correct for chromatic aberration, making them ideal for precision instruments.

High-Performance Optical Applications

In high-performance optical applications, the Abbe value is a critical factor in selecting materials.

For example, scientific instruments like telescopes and microscopes require optics that offer excellent clarity and minimal distortion.

Using materials with lower dispersion is vital to achieving high-quality images through these devices. Manufacturers prioritize lenses with elevated Abbe values to minimize chromatic aberration, enhancing visual accuracy.

Materials and Measurement in Optics

Optical materials play a crucial role in the performance of lenses and other devices. Understanding how these materials are classified and measured helps in selecting the right components for optical systems.

Glass Code and Optical Glass Classification

Optical glasses are categorized using a specific glass code system. This system simplifies the selection process for designers and manufacturers. Each optical glass has distinct properties, including Abbe value, index of refraction, and specific gravity.

Commonly used optical glasses include N-BK7 and high-index lenses. N-BK7 is known for its excellent optical qualities and widely used in many applications. High-index lenses reduce thickness while maintaining clarity, making them popular for complex optical designs.

Glass codes provide a shorthand to identify key characteristics, minimizing confusion in glass selection. Understanding these classifications helps technicians choose the right glass for desired focal lengths and optical performance.

The Sellmeier Equation and Calculation of Abbe Numbers

The Sellmeier equation is essential for calculating the refractive index of optical materials at specific wavelengths. This equation helps predict how light will behave as it passes through different materials.

The Abbe number, often represented as V, quantifies light dispersion in a material. A higher V value indicates less dispersion, which leads to improved optical performance and reduced color fringing. For example, materials with Abbe values above 50 are typically preferred in high-quality lenses.

By using the Sellmeier equation, manufacturers can optimize the design of optical devices to enhance clarity and precision. This careful calculation ensures that all parameters work together smoothly, leading to better visual results.

Standardization of Refractive Index and Abbe Values

Standardization is vital for comparing different optical materials. Industry standards specify the refractive index and Abbe values for various optical glasses.

This helps manufacturers and researchers easily select and test materials. Common standards include those set by organizations such as the International Organization for Standardization (ISO).

These standards ensure that everyone uses the same criteria, which simplifies collaboration and product design. Thus, when designers list an optical material’s properties, it’s typically done against these standardized measurements.

This approach supports accuracy and consistency in optical engineering, fostering innovation and reliability in products.